01

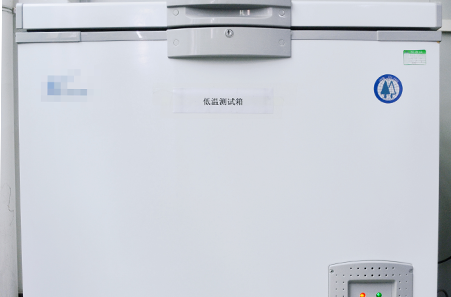

Low Temperature Resistance Tester

Since its establishment, ZHILI has introduced a variety of inspection equipment, which can independently test the service life of gas springs and buffers, simulate high and low temperature environment for product quality testing, and also meet the customer's requirements for salt spray testing, and gas spring curve testing equipment can directly test the function of the product and provide detailed parameter content for customers. From material accessories to finished products, these professional inspection equipment, to provide a more powerful guarantee for our technical team, showing the professionalism and comprehensiveness dedicated to the product.

Low Temperature Resistance Tester

Fatigue Testing Machine --For Gas Spring

Force Curve

High Temperature Resistance Tester

Force testing machine

Salt Spray Tester

We are committed to the tenet of "treating people with integrity" and "putting people first", constantly innovating technology and improving products to serve our customers with excellent products. On the basis of our existing facilities, we have been updating our production equipment, increasing production efficiency, improving production processes, and complementing our advanced testing equipment and professional quality personnel, we have obtained a number of national and provincial invention patents and technological innovations in recent years.

2021-02-17

2021-05-09

2021-08-20

2021-07-11